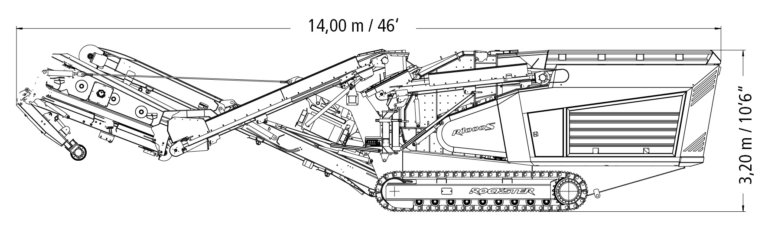

R 1000

Tracked

Impact Crusher

38" x 29"

960 x 720 mm

Inlet opening

up to 280 t/h

depending on material

78,300 lbs

35,5 t

Weight incl. screening system

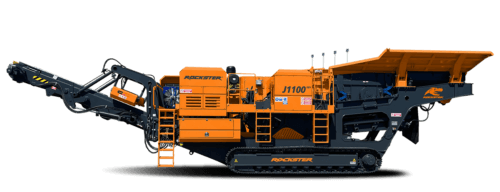

R 1000

The ALL-IN-ONE Crusher.

- Tier 4 Final / STAGE V Engine - 250kW / 340HP

- Hydrostatic crusher drive for consistent throughput

- Individually & hydraulically adjustable 2 swing beams

- Unique double-functional return- or stockpile belt

- Optional Air Blower for seperation of light non-mineral materials

Track-mounted impact crusher R1000 is especially designed to increase efficiency as well as operational safety. Easy to use, it includes a wide range of technical refinements that make a daily job easier and more cost-effective.

R 1000

Technical refinements for an optimal crushing process

Central machine control with a fully authomatic monitoring

Sophisticated and easy-to-use multifunctional color display with various quick start functions (Different settings for a variety of applications)

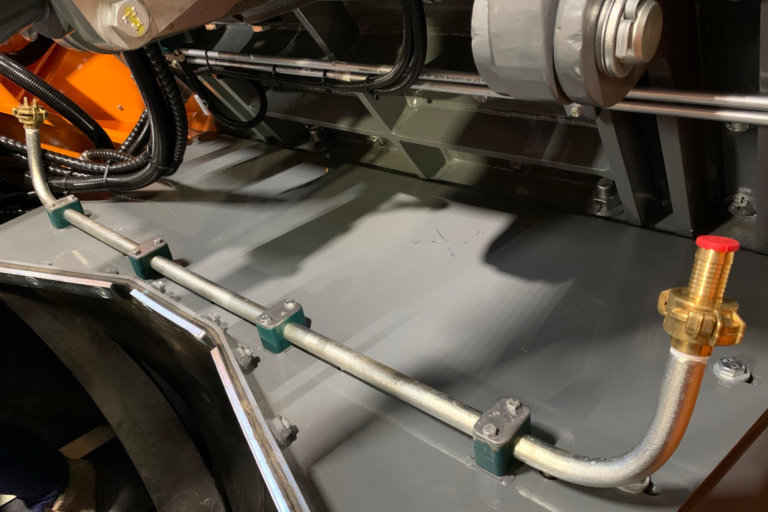

Vibrating hardox discharge chute

No wear of the main belt, especially beneficial when crushing steel-reinforced concrete

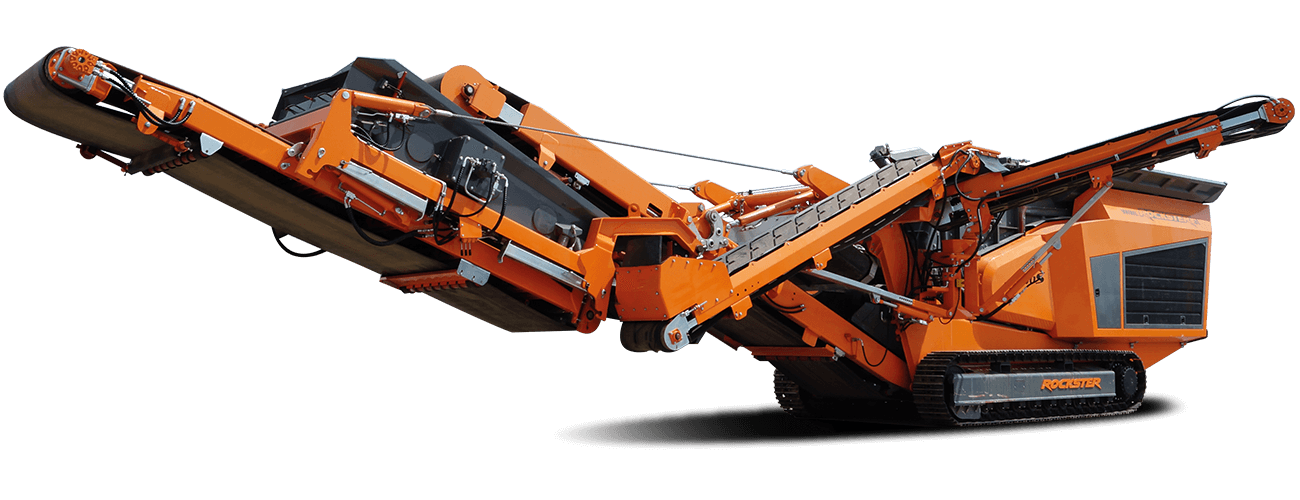

R 1000

Options

RS100 Screen box and RB92 double-functional return-/ stockpile belt

Optimal option for production of 100% defined end-product

Air Blower RVB1700

Efficiently separate light non-aggregates such as plastic, paper, textile, cardboard, wood, ythong, styrofoam, which results in a cleaner and higher quality final product.

R 1000

Job Stories & Videos

R 1000

Technical data

Key facts & Performance

Key facts & Performance

| Inlet opening: | 960 x 720 mm / 38“ x 29“ | |

| Impact circle diameter: | 1020 mm / 40“ | |

| Rotor equipment: | 4 blow bars | |

| Crushing ration: | 1:10 – 1:50 | |

| Performance: | up to 280 t/h / 310 st/h | |

| Rotor speed (continuously adjustable): | up to 850 rpm | |

| Weight: | 9,000 kg / 19,850 lbs | |

| Drive unit: | hydrostatic | |

| Gap adjustment (adjusted on display): | fully hydraulic | |

| Dust suppression: | At the crusher inlet & outlet |