Asphalt, concrete, c&d waste,

brick & natural stone

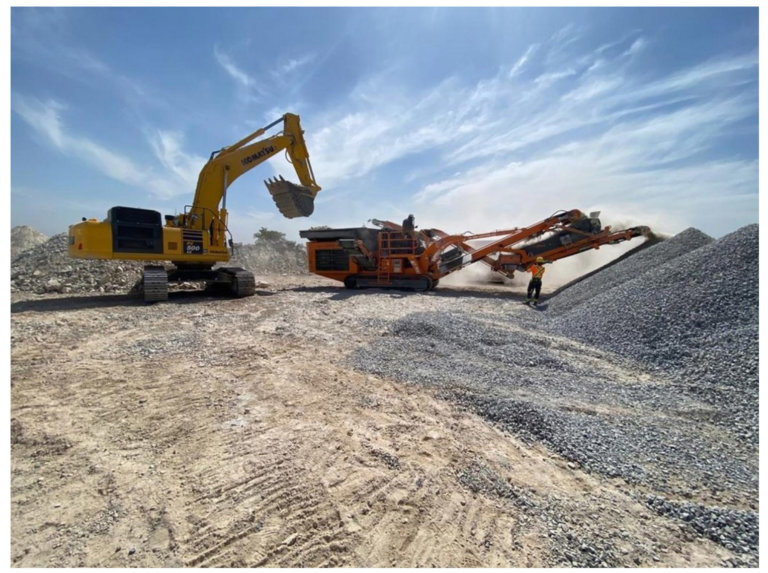

Track-mounted

Impact- & jaw crusher

Rockster: Efficient, flexible & reliable

Recycling of C&D waste, asphalt, concrete, bricks and processing of natural stone.

Austrian based manufacturer, Rockster Austria International GmbH has a longlasting reputation and the know-how in demolition and screening industry.The product line includes, among others, track mounted impact & jaw crushers, screening machinery, feeder conveyors and tracked stackers. Impact Crusher & Jaw Crusher, screening machinery , feeder conveyors and Tracked stackers.

Our mobile crushers and screeners are used for profitable & economical recycling and processing of asphalt, concrete and construction waste, as well as for natural stone. With innovations like The Original DUPLEX system or double-functional return belt, we repeatedly demonstrate our progressive approach towards improving and developing more efficient recycling & processing methods.

Competence

Progress

Partnership

Products

Our crushing & screening plants

Dealers &

Distribution partner

Discover our global network of distribution partners. Rockster Austria International GmbH works with first-class partners worldwide to offer innovative processing and recycling solutions.